|

Gyroplane Maintenance SafetyMaintenance safety is rarely given its due credit. In a majority of all aviation accidents it is the pilot or components that initiates a series of events that lead to a mishap. This general statement is true for a majority of the industry but as we can see from the NTSB data presented in the general gyroplane safety section we know that we can be the cause of those component failures. Regardless of what or for whom you are working on any aircraft a very good understanding of the aircraft, its systems and operational limitations are needed to troubleshoot, identify (inspect), and take the appropriate maintenance action. In certificated aircraft, maintenance technicians have authorized maintenance and repair manuals, reference manuals (which are not approved maintenance publications but acceptable) and they have factory representatives to give guidance and provide feedback to the factory engineers. Our homebuilt gyroplane does not come with maintenance manuals of any kind. You do get the assembly manual which is good information. If your gyroplane is also affored as an LSA aircraft you might try and see if the manufacturer has a maintenance manual as part of the required maintenance/inspection authorization that you can purchase. The more resources and reference material the better, recall we need a maintenance knowledge foundation. These resources will help you form that foundation. You can also look into taking a maintenance program. I mean how many gyroplanes have you worked on in the past, how much actual wrench turning have you done on your gyroplane since you assembled it? Again if the kit is offered in LSA form the manufacturer should have a maintenance course. For those who have built from plans or the kit is not offered as an LSA there is still another option, Fun-Air LLC offers a very reasonably priced gyroplane maintenance course with several variety of gyroplanes to work on.

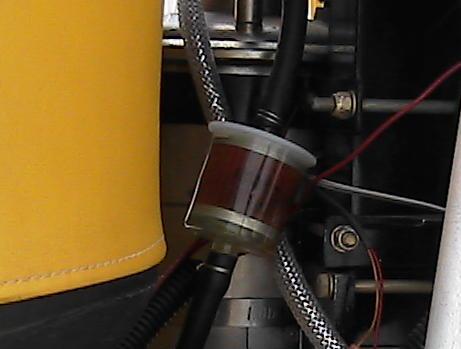

Engines & Fuel Systems

Engines and fuel systems are the leading cause of all homebuilt mishaps (fixed and rotary wing). So be sure to do all the recommended maitenance, break in and overhaul or replacement as well as servicing that the kit manufacturer recommends. Be sure not to doze off during these topics when taking a maintenance course. To most people in general I would think the ability to have a formal classroom instruction followed by actual hands on application is the best instruction for any maintenance course. This is what the certificated aircraft manufacturers offer to A&P's so why not go to a good gyroplane maintenance course?

The kit manufacturer may be able to help so don't rule them out. The big difference is they do not have the resources like a major manufacturer but that doesn't mean to not give it a shot. Repair & overhaul companies can also give some tips to help you troubleshoot. Of course troubleshooting means we have identified a problem and are taking steps to find the cause, repair or replace the fault to correct the situation. Please, please, please keep in mind parts do not fix themselves, problems only get worse not better, and there is absolutely no reason to fly a gyroplane that is not in a safe condition to fly. The safest place is on the ground until repairs have been made and the aircraft has been found to be in a safe condition for flight. Inspections are a preventive and troubleshooting action. Regular, periodic inspections can reveal an issue before it gets out of limitations. Looking to see if control tubes are hooked up during a preflight is not the same as physically checking the indicated play (wear) on a control bearing. How would you ever know your engines true health if you do not perform a compression check? Is any of this important? Is your life, your wife, kids or friends lives important? Trying to cut corners, using inferior products, or using unacceptable maintenance practices increases the risk factor of you having a mishap. So what to do if you can't get factory support, have no maintenance manual and cannot afford to attend a maintenance course? At the very least get a copy of FAA publication AC 43.13-1. It is to be used to supplement the information which the manufacturer may not supply. The manufacturer is like God and AC 43.13 is like an angel. When God talks the angles listen. If Gods not there and an angle speaks to you, you better listen. Use your data in similar fashion. The maunfacturers data takes pecedence over everything. When nothing else exists AC 43.13-1 is the next best option for the homebuilt gyroplane mechanic.

AC 43.13-1 is chocked full of information on hardware inspection, fabrication, acceptability criteria and much more.

Human Factors in Gyroplane Maintenance

As part of the aviation safety program the FAA implelmented a personal minimums checklist. The checklist presents you with some questions to ask yourself before and after the task you are about to perform. A similar version of this checklist is available for you to view and print for free by simply following the link provided.

Gyroplane Maintenance "Personal Minimums" Checklist

The Aiplane Owners and Pilots Association (AOPA) has some really great interactive safety treaining seminars online. You can apply for a free registration and choos from many topics to perform your flight, mission and become more educated. The following link is just one example and is an interactive training seminar on the aircraft engine and propeller. Enjoy and Stay Safe.

|